Our mission: We create feel-good moments and spaces using premium ceramics

Always at the forefront of our endeavours is our strong understanding of the needs and wishes of our customers. This knowledge affords us the pleasure of being instrumental in helping to create a particular character for every home. Your home should be comfortable so we imbue our products with all our passion, creativity and design expertise, and pair it with our technical and conceptual know-how. With our brands, lifestyles and price segments, we offer both superior individual items for your home and perfect complete solutions.

Our vision: A house becomes a home

A “home” is created only when a house is furnished in a way that reflects the personal vision and style of those who live in it. We help make this happen – for everyone, everywhere.

Close

RESPONSIBILITY

The environment is important to us. We are committed to combining financial performance with environmental protection in the long term.Combining financial performance and environmental protection is the aim of all sustainability activities at Villeroy & Boch. Key focuses include improving the efficiency of energy and raw materials, preserving resources by optimising production processes, reducing volumes of waste water and pollution, as well as emissions of CO₂ and other waste gases.

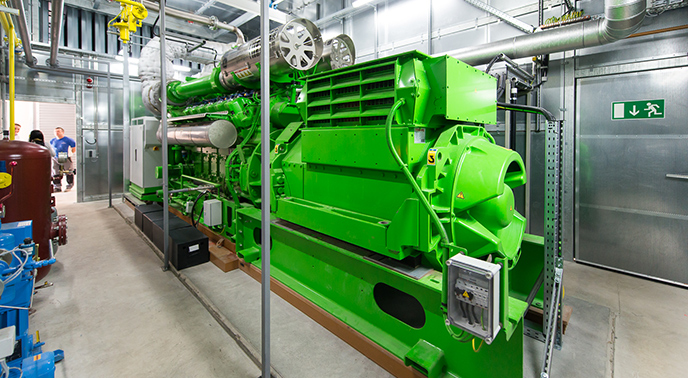

Efficient energy with the company's own thermal power station

Protecting the environment, reducing CO₂ emissions and ensuring the responsible use of resources: Villeroy & Boch has been making an important contribution to these issues since the commissioning of the thermal power station at the Bathroom and Wellness production site in Mettlach in 2014. The natural gas-fired thermal power station produces around 15,000 MWh of heat and 15,700 MWh of electricity each year – representing around 90 percent of the site's total electricity requirements. The environment is reaping the benefit of this energy concept, with an annual reduction in CO₂ emissions of some 4,000 tonnes. This is the result of the plant’s greater efficiency and the fact that using gas allows simultaneous generation of both heat and electricity. The Villeroy & Boch group has set itself the target of reducing its specific energy consumption (electricity and gas) by 15% across all group sites by 2024 at the latest.

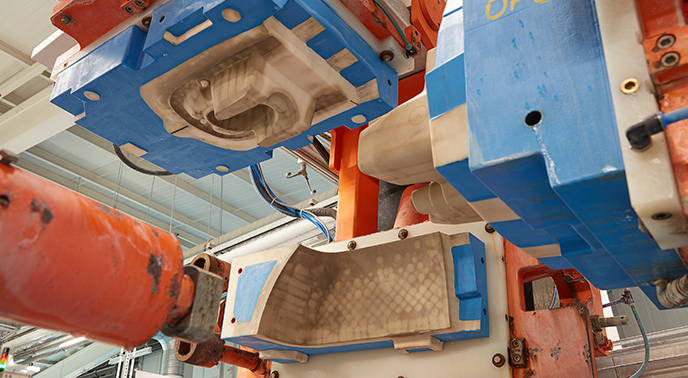

Die-casting process – sustainable moulding

Two different casting processes are used in ceramic production: battery-casting and die-casting. As well as the energy-intensive battery-casting process, Villeroy & Boch is increasingly relying on the more energy-efficient die-casting method. A special feature of this process is that the water is removed from the liquid slip at high pressure and from the resin mould through a vacuum effect. Any remaining liquid slip is rinsed with water after the part has formed. While this increases water consumption, it reduces the energy required for the moulding process by a whole 90 per cent in comparison with the conventional procedure.

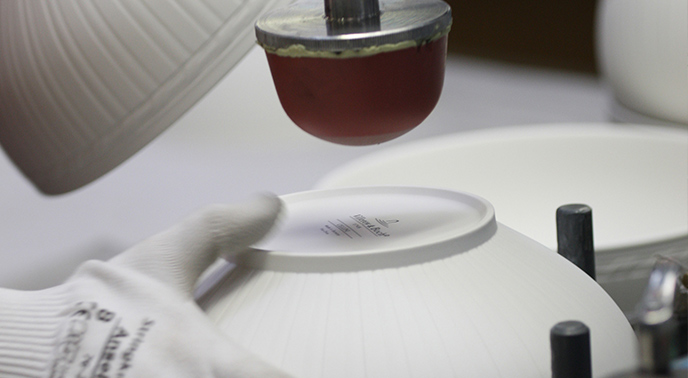

Integrating environmental technology in the production process with a micro-filtration plant

Increasing raw material productivity while minimising energy consumption: this is the role of the micro-filtration plant at Villeroy & Boch. The optimal procedure for recycling glazes was established as part of an environmental project. The modern micro-filtration plant will allow the recovery of several hundreds of tonnes of glaze each year. The positive energy balance is clear: with a projected annual saving of around 30 tonnes of CO₂.

Roden: Sustainable energy generation using solar panels

The Dutch town of Roden enjoys over 900 hours of sunshine. Villeroy & Boch is making use of this asset to generate energy around the clock while reducing its CO₂ footprint. The 2,000 solar panels installed on the roof of the production area cover 17% of the required power – that is equivalent to using 1,000 tonnes of CO₂ and 500,000 kWh a year.

Energy-efficient production sites thanks to environmental and energy management systems

All over the world, reducing consumption of energy, water and raw materials as well as CO₂ emissions is a key priority at Villeroy & Boch's 13 production sites in Europe and Asia. A requirement for comprehensive precautionary environmental planning has been formulated in the Villeroy & Boch group's environmental and energy policy. The environmental impact of energy consumption makes reducing energy a top priority for Villeroy & Boch. The group's standards for the environment and energy consumption are based on two management systems according to an international standard.Both management systems include the setting of environmental and energy targets, with progress checked at regular intervals. Many of Villeroy & Boch's international production sites are certified according to the environmental management system DIN EN ISO 14001 and the energy management system DIN EN ISO 50001, and regular audits are conducted to verify compliance with their requirements.

Close